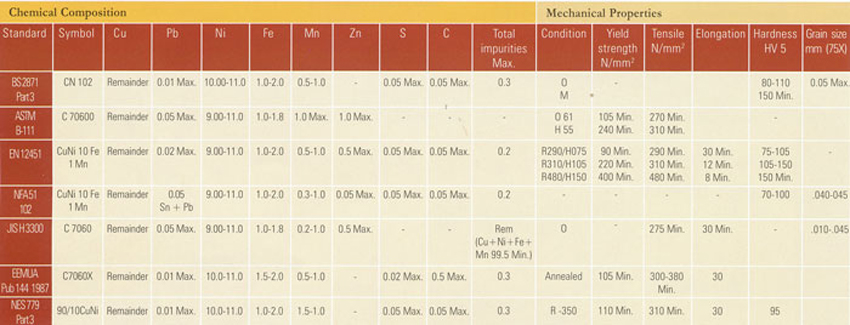

| Standard |

Symbol |

| ASTM B 111 |

C 70600 |

| BS 2871 Part 3 |

CN 102 |

| EN 12451 |

CuNi10 Fe 1Mn |

| NFA51 102 |

CuNi10 Fe1Mn |

| JIS H 3300 |

C 7060 |

| EEMUA Pub 144 1987 |

C7060X |

| NES 779 Part 3 |

90/10 CuNi |

| Guide to selection of tube materials |

| Sea Water |

| Dissolved salts from 1500 to 3000 ppm |

| Suspended solids more than 25 ppm |

| H2S or Ammonia less than 1 ppm |

| Permissible average velocity of water 3.0–4.0 meter / sec. |

| Product Applications areas |

| Chillers |

| Heat Exchangers & Condensers |

| Power Plants |

| Refineries |

| Desalination Plants |

| Ship Building & Ship Repairs |

| Defense |

Curpo Nickel Tubes 95/5 & 90/10 for Marine Application

These Cupro Nickel tubes & pipes for Marine application are very important for all Industrial fields. The company has experience in these areas and is able to supply these tubes in accordance with most international standards and special customer requirements.

Cupro Nickel Tubes 90/10 for Heat Exchangers & Condensers

These Cupro Nickel tubes & pipes for Heat Exchangers & Condensers are very important for all Industrial fields. The company has experience in these areas and is able to supply these tubes in accordance with most international standards and special customer requirements.

Cupro Nickel Tubes 90/10 for Automobile Industries

The Move To Copper-Nickel Tubing

Copper had been proved since the early days to have many good attributes. It was easy to bend and had very high corrosion resistance, but there was concern about its low corrosion-fatigue strength. When copper-nickel was introduced, it displayed corrosion resistance similar to copper, higher general strength and better fatigue strength. Good formability allows ease of flaring and bending, and although the metal cost is greater than that of steel alternatives, copper-nickel is very attractive in view of its extra life, trouble-free installation and safety/reliability characteristics.

Properties of Copper-Nickel Brake Tubing

The copper-nickel alloy used for brake tubing typically contains 10% nickel, with iron and manganese additions of 1.4% and 0.8% respectively. The product conforms to ASTM B466 (American Society for Testing and Materials), which specifies dimensions, tensile strength and yield strength. Formability and internal cleanliness conform to specifications SAE J527, ASTM A254 and SMMT C5B (Society of Motor Manufacturers and Traders). Also, the alloy meets the requirements for pressure containment, fabrication and corrosion resistance for ISO 4038 (International Standards Organization) and SAE J1047.

Corrosion Resistance

For many years prior to its application as a brake tubing material, alloy C70600 had been used in ships, power station condensers and hydraulic lines on tankers, and had displayed excellent resistance to saline conditions. Early tests revealed that copper-nickel has almost the same resistance to burst pressure as steel. In testing, however, when exposed to salt spray over 180 days, steel's burst strength decreases significantly. The copper alloy remains consistently resistant.

For tubes covered with a moist, salty mudpack for six months, brazed steel was severely corroded resulting in perforation of the tubing wall; whereas, only superficial general corrosion was found on the copper-nickel tubing. ISO 4038 and SAE J1047 include a corrosion resistance requirement referring to ISO 3768 asking for a minimum burst pressure of 110 MPa after 96 hours in neutral salt spray. Swedish requirements include a resistance at least equal to 25µ of zinc. In all cases alloy C70600 easily exceeds the required corrosion resistance.

Copper-nickel brake tubing provides superior reliability and assures both manufacturers and vehicle owners improved durability for effective long-life functioning of the brake system.

| Cupro Nickel Rods 90/10 and 95/5 |

Cupro Nickel Rods For 90/10

Chemical Properties |

| Pb |

0.05 Max. |

| Fe |

1.00 - 1.80 |

| Mn |

1.00 Max. |

| Zn |

1.00 Max. |

Cu + Ag Remainder Ni + Co 9.00 - 11.00

Mechenical Properties

Light Drawn |

| Flattening Test |

Reqd. (After 'O') |

| U.T.S. ksi |

45.00 Min |

| Y.S. at 0.5% Ext. ksi |

35.00 Min. |

Expansion Test 30% at 60 degree Reqd. (After 'O')

Annealed Temper |

| Flattening Test |

Reqd. |

| Grain Size at 75 X mm Avg. |

0.010 - 0.045 |

| U.T.S. ksi |

40.00 Min. |

| Y.S. at 0.5% Ext. ksi |

15.00 Min. |

Expansion Test 30% at 60 degree Reqd. |

|

Cupro Nickel Rods For 95/5

Chemical Properties |

| Sn |

0.10 Max. |

| Pb |

0.05 Max |

| Ni |

4.00 - 5.00 |

| Fe |

0.10 Max. |

| Mn |

0.25 Max. |

| As |

0.10 Max. |

| Cu + Ag |

95.00 - 96.000 |

| Sb |

0.01 Max. |

| Bi |

0.0025 Max. |

Oxygen (O2) 0.08 Max.

Mechenical Properties

Annealed |

| U.T.S. MPa |

216 - 275 (Strip cut from Ring Tube) |

| %Elongation at 5.65Sq.Rt So G.L. |

40.00 Min. (Strip cut from Ring Tube) |

| Flattening Test |

Reqd. |

| Bend Test |

Reqd. (180 degree close) |

|

|